A long time viewer of my Bilibili channel contacted me to do a restoration of his Korg Triton.

Summary

The Korg Triton is a synthesizer and sampler workstation available from 1999. It has a resistive touchscreen. The unit was sent to me and was in working condition.

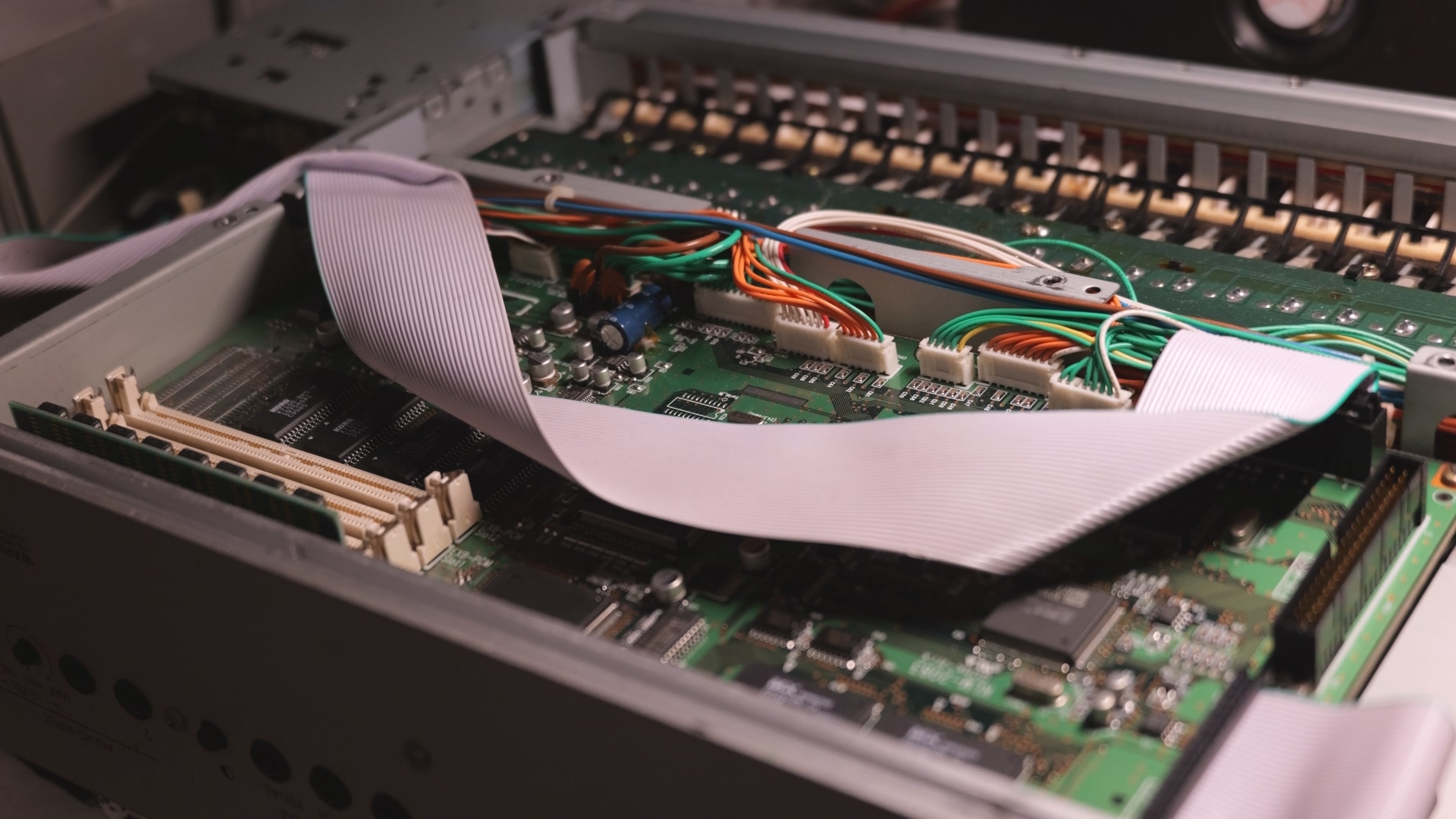

Inspection

The owner complained about low volume of the analog input, control buttons not working well, joystick issue and an encoder that’s jumping around. Upon arrival I did a functional test using the built-in test mode and found no problem with analog input or output, but all other issues are there and also the touch controller need adjustment. In addition, one of the plastic side cover is cracked. Some of the molded-in boss were broken.

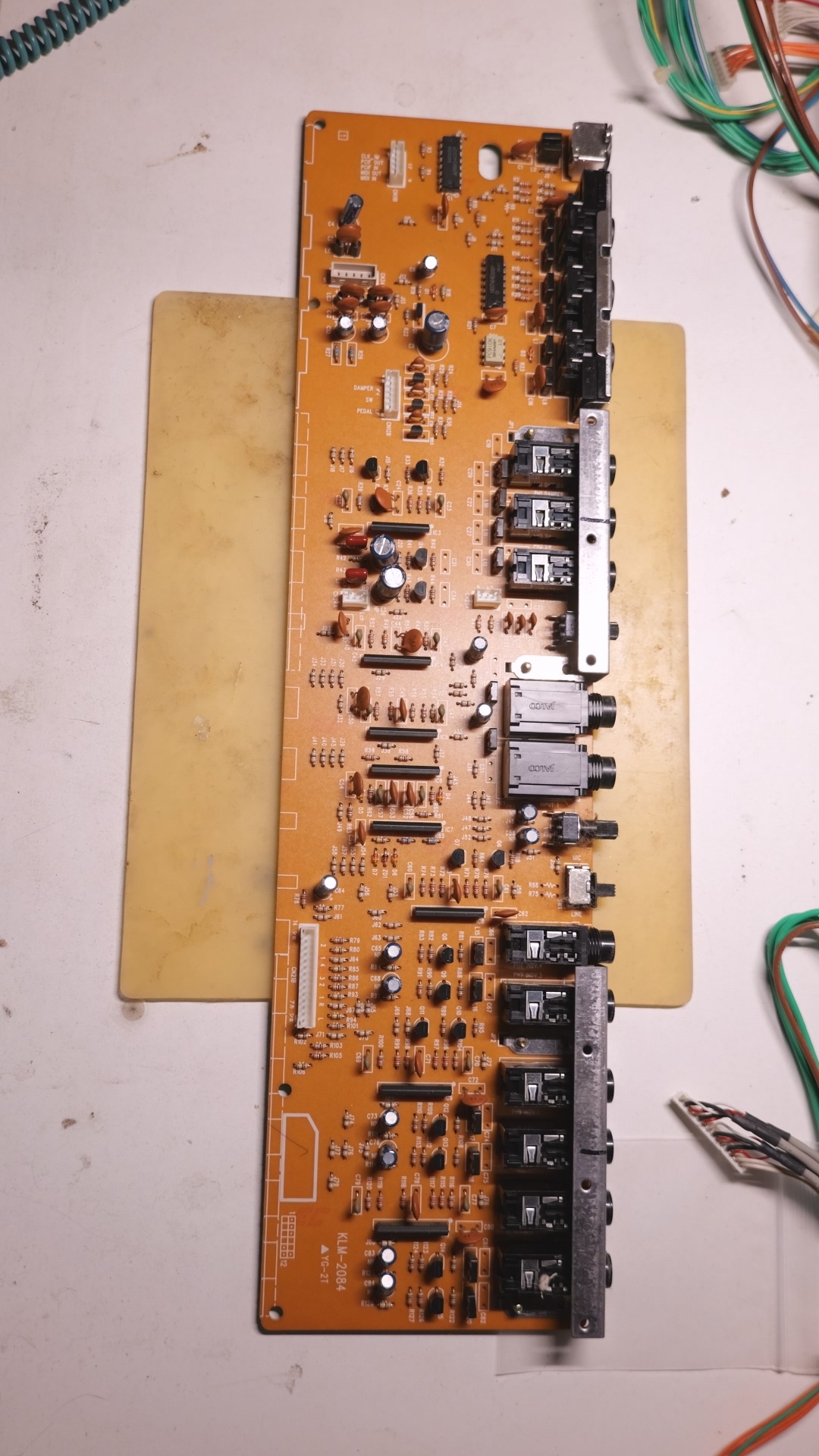

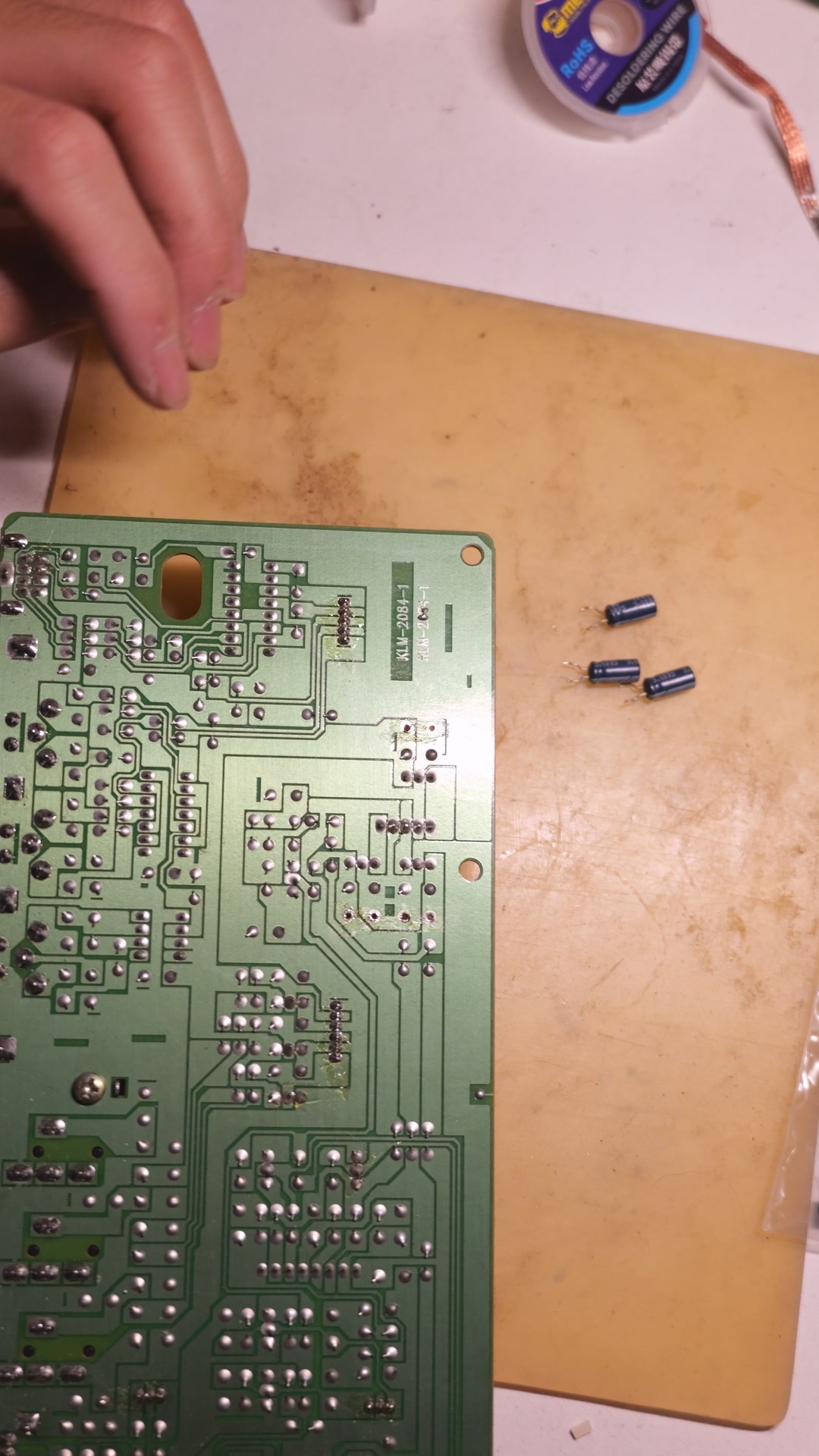

Checking Capacitors

Since the owner complained about the analog part, I removed some capacitors from each section of the board and tested them with LCR meter, including analog in, analog out, power capacitors on the main board and PSU. All of those tested fine so I chose to not replace any of them.

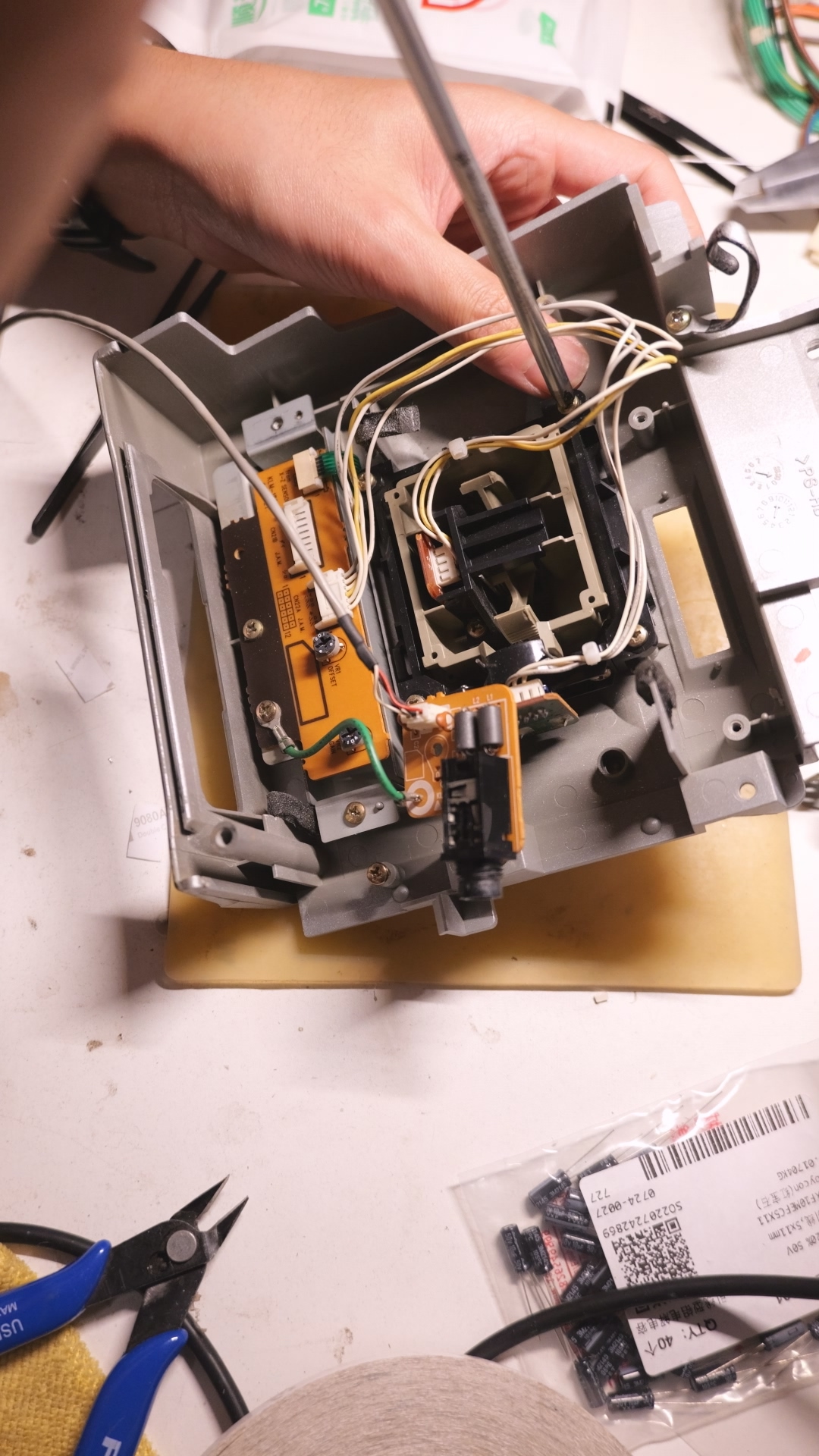

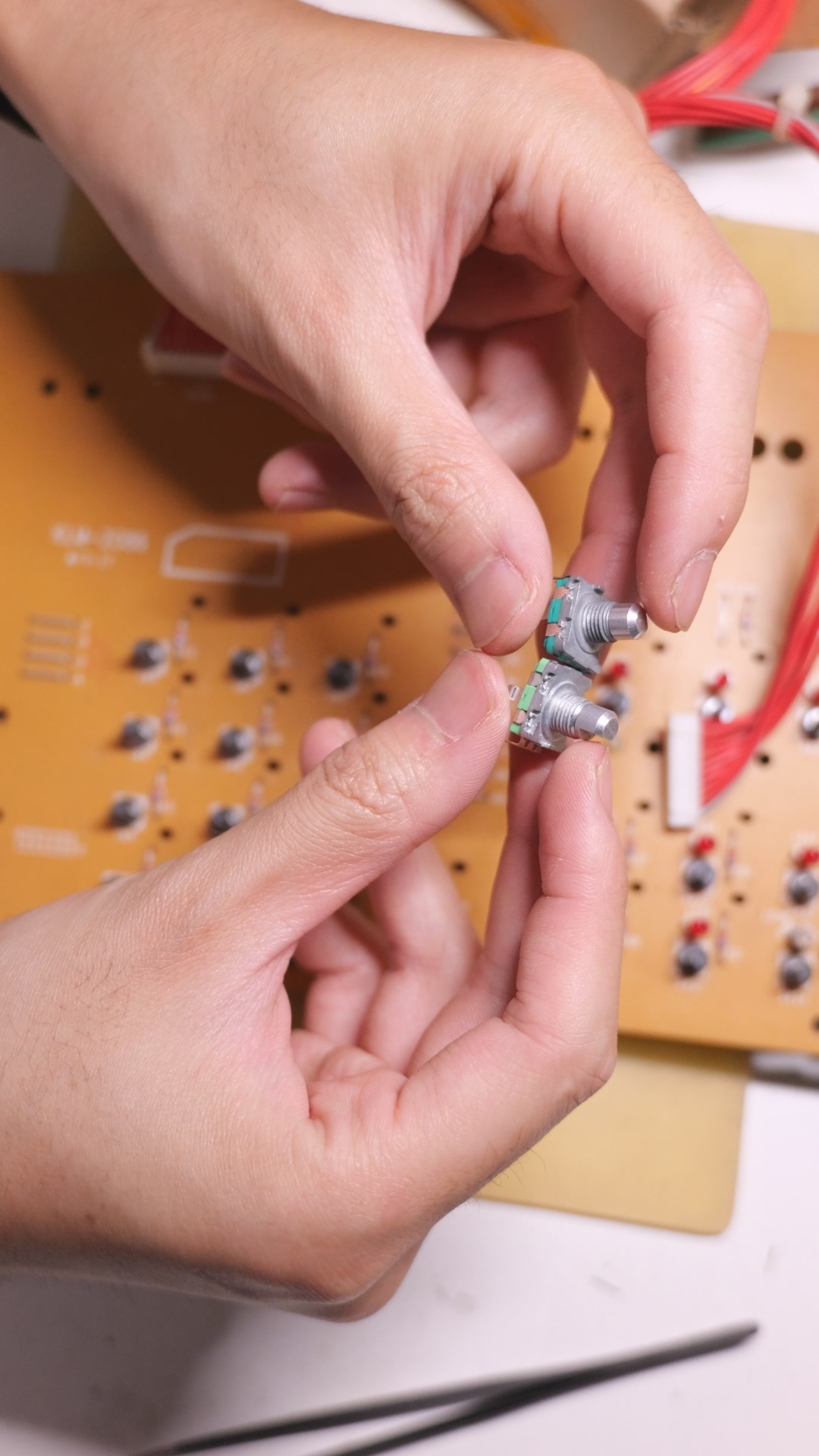

Repairing Joystick

The joystick has a lot of play on both X and Y axis and will stuck when moved to the right. The nut of the potentiometers are all loose which caused this issue. I put thread-lock glue and tightened the nuts. I also put some glue on the shaft so that the handle won’t slide on the shaft.

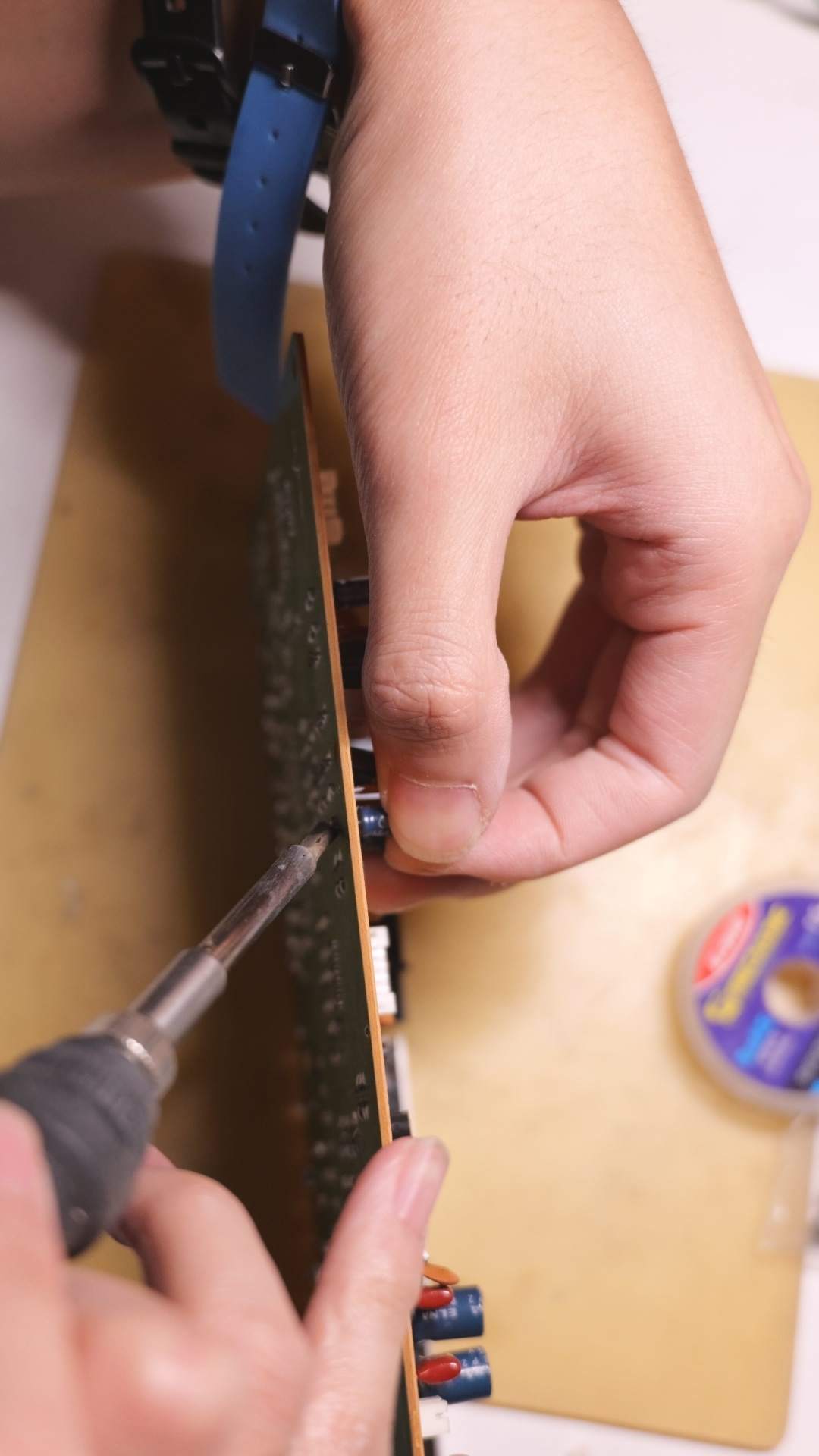

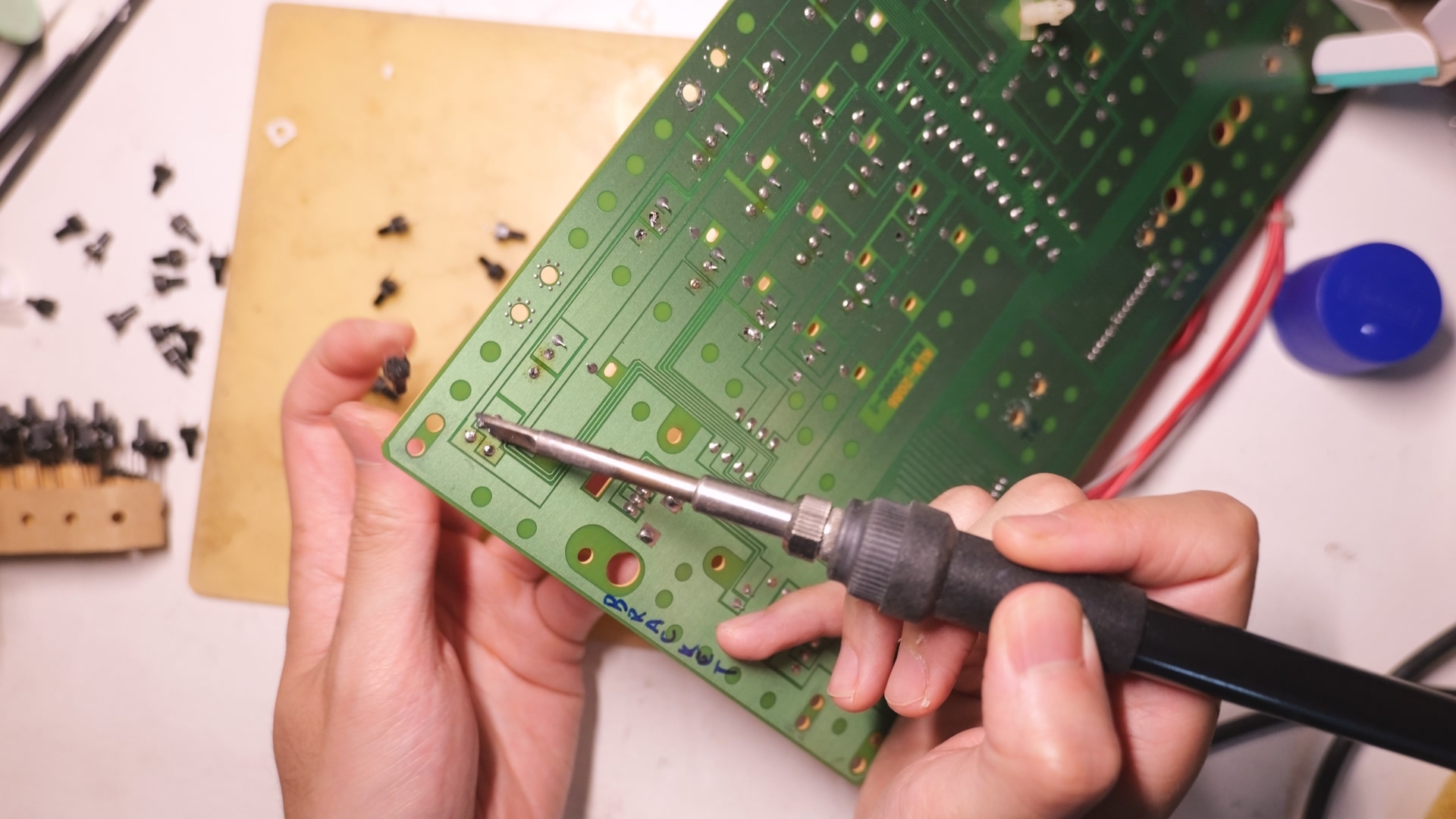

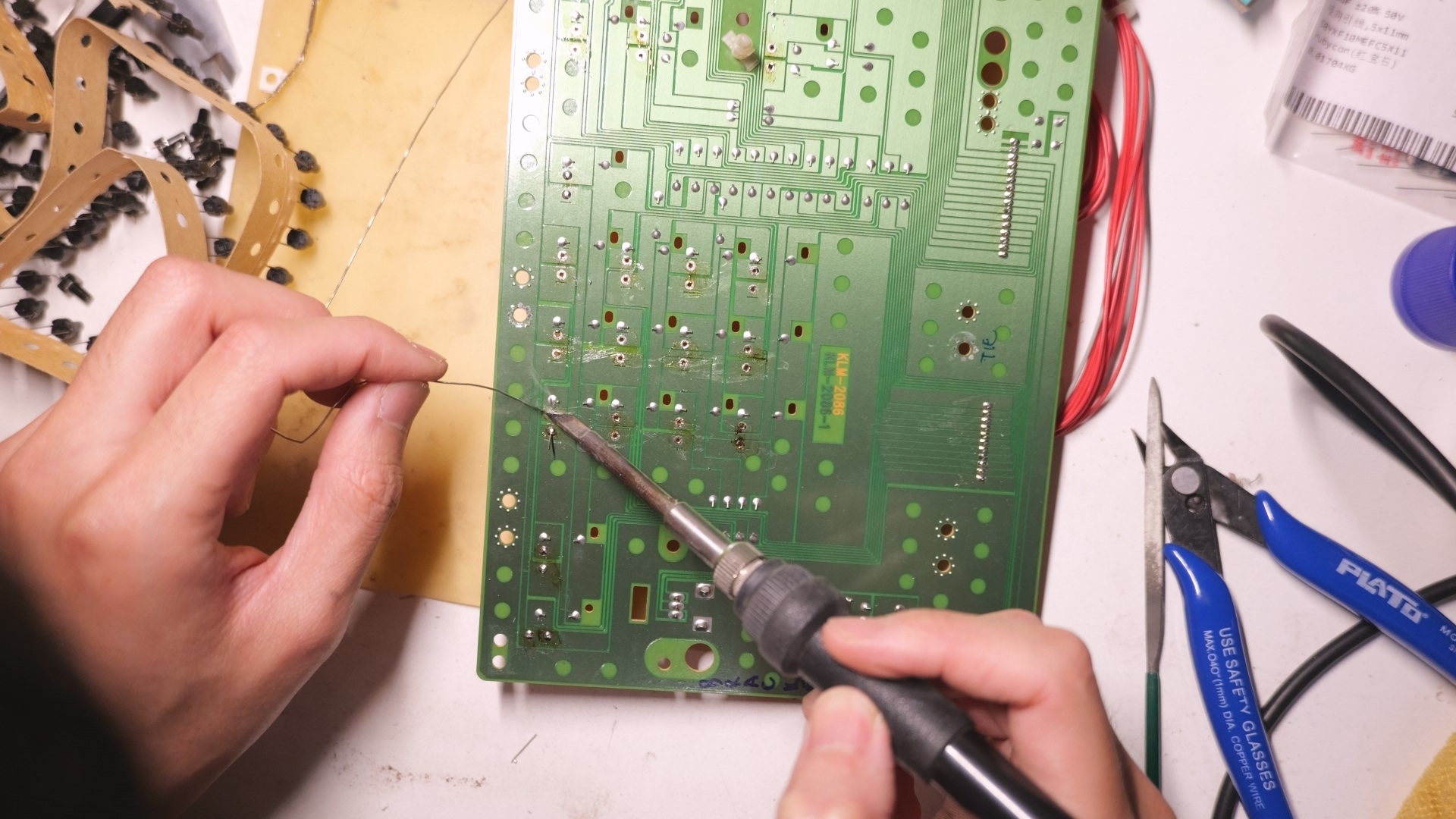

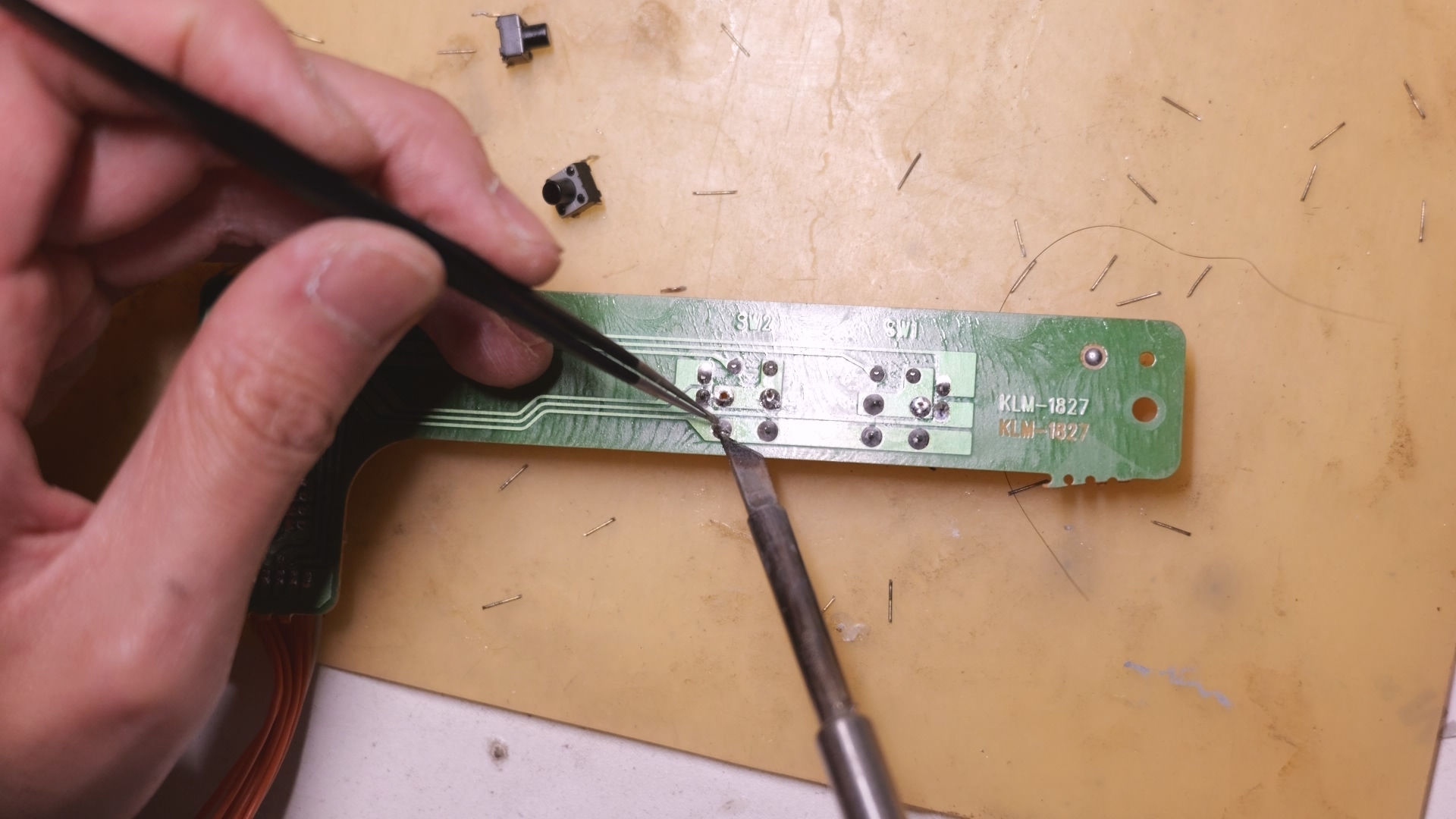

Replacing the keys

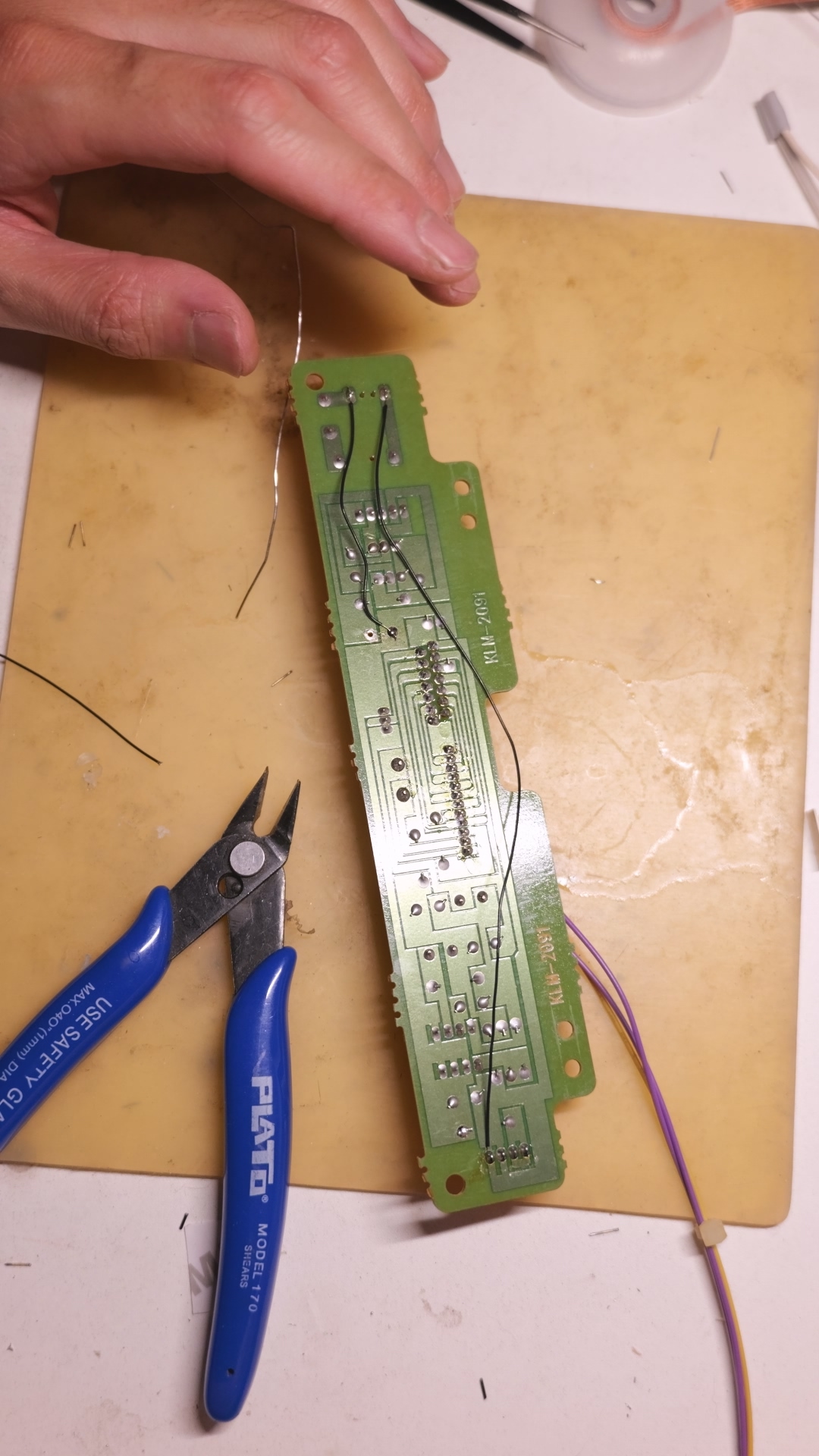

This is relatively simple and straightforward. Just remove all tactile switches and replace with new ones. I couldn’t fine exact same button so I replaced with ones that has a little bit higher actuation force. Most of the buttons are 2-pin and is not easy to source, while the assignable buttons are standard 4-pin.

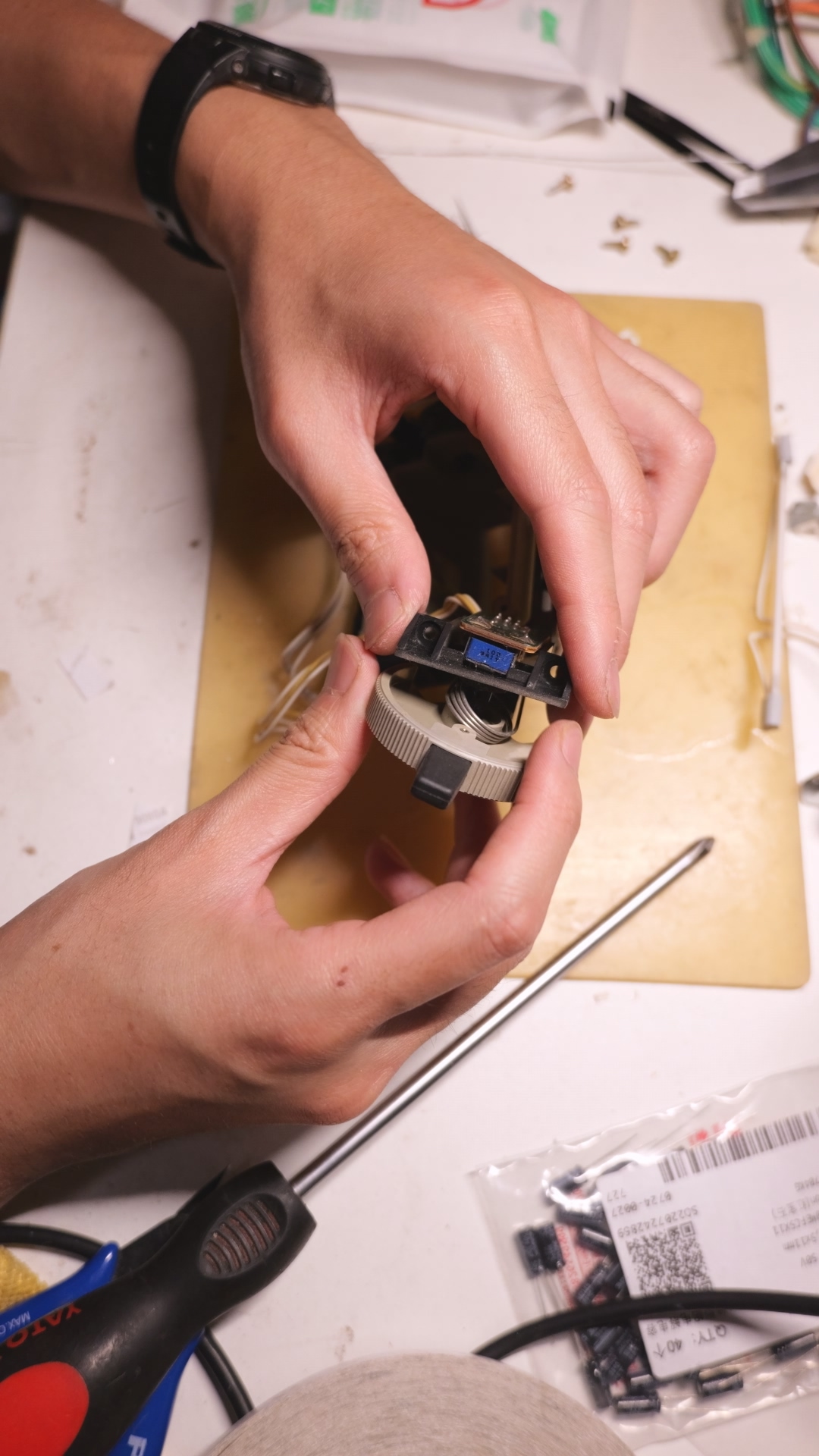

Replacing the Encoder

The encoder is still acting up after blasting with contact cleaner. I bought a new one but it’s not the same spec which resulted in 2 pulses with one detent of rotation. I couldn’t find anything to match the original spec and it was too expensive to custom order, this was the best I can do which I’m not satisfied with.

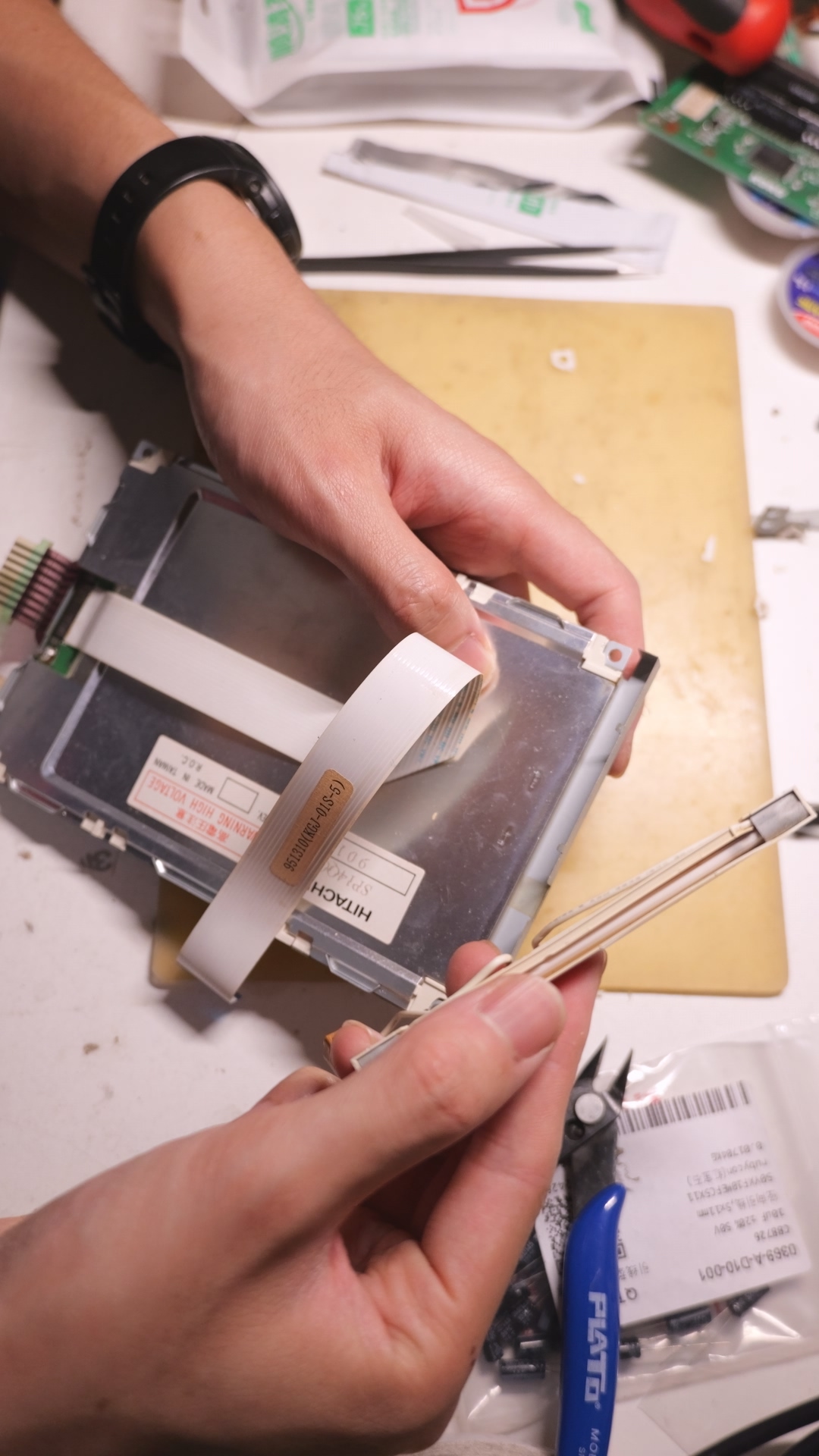

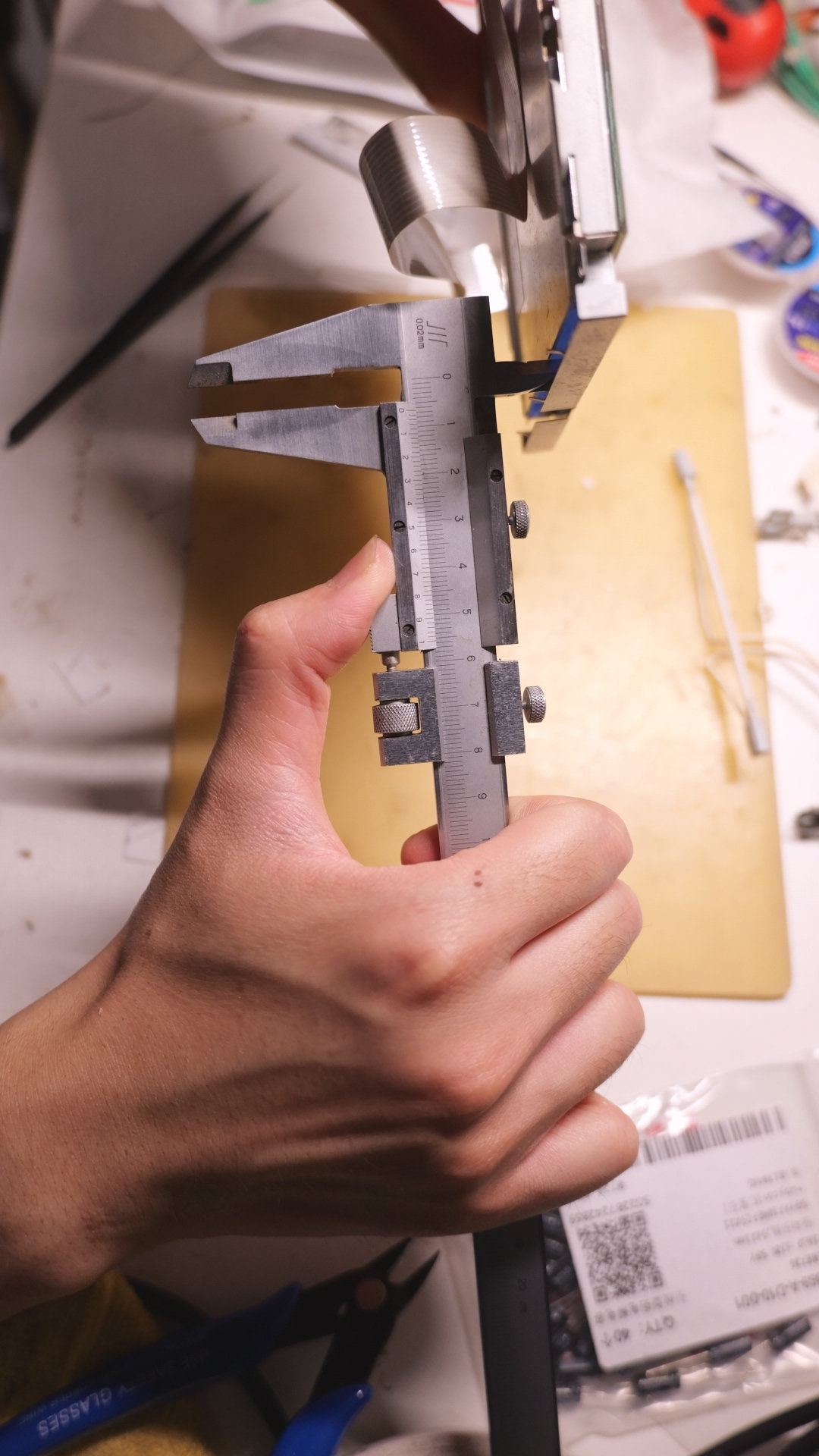

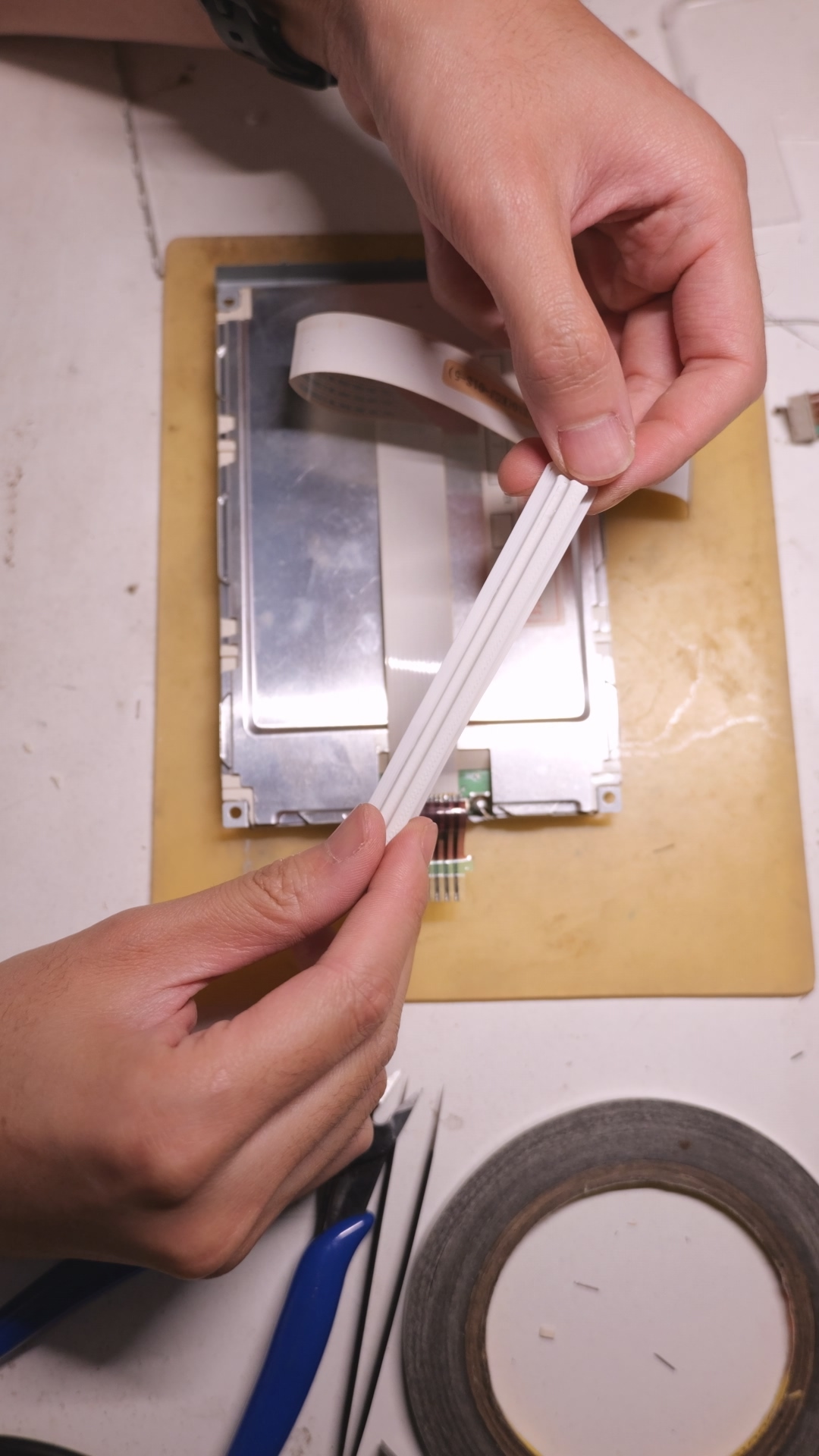

Modify Backlight

The original backlight of the LCD screen is CCFL which has faded over time. I replaced it with LED backlight stripes for industrial control screen. The original mounting bracket for the CCFL is not reusable and it also shattered while I tried removing it. So I 3D printed a new bracket to accommodate the LED stripe.

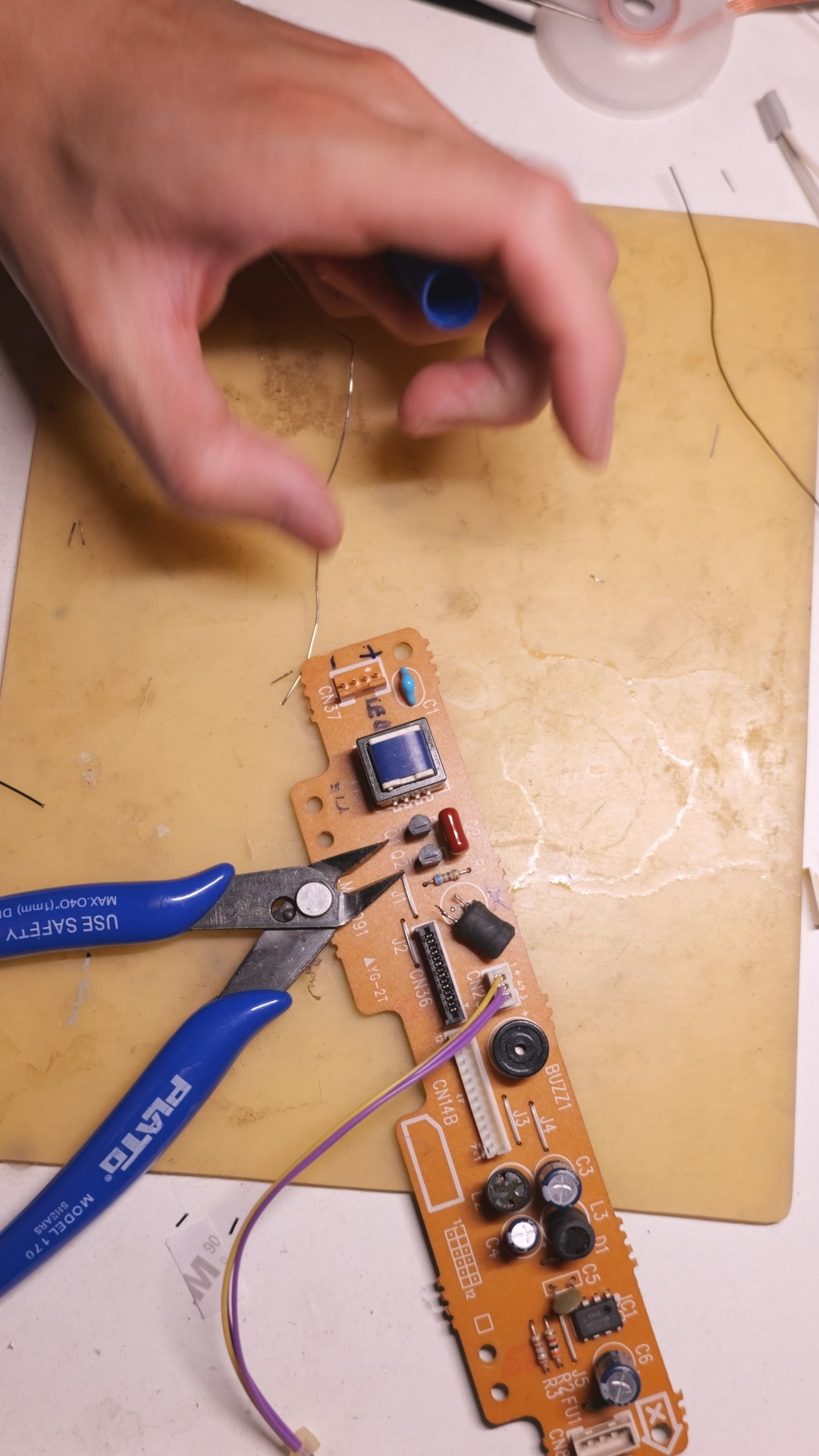

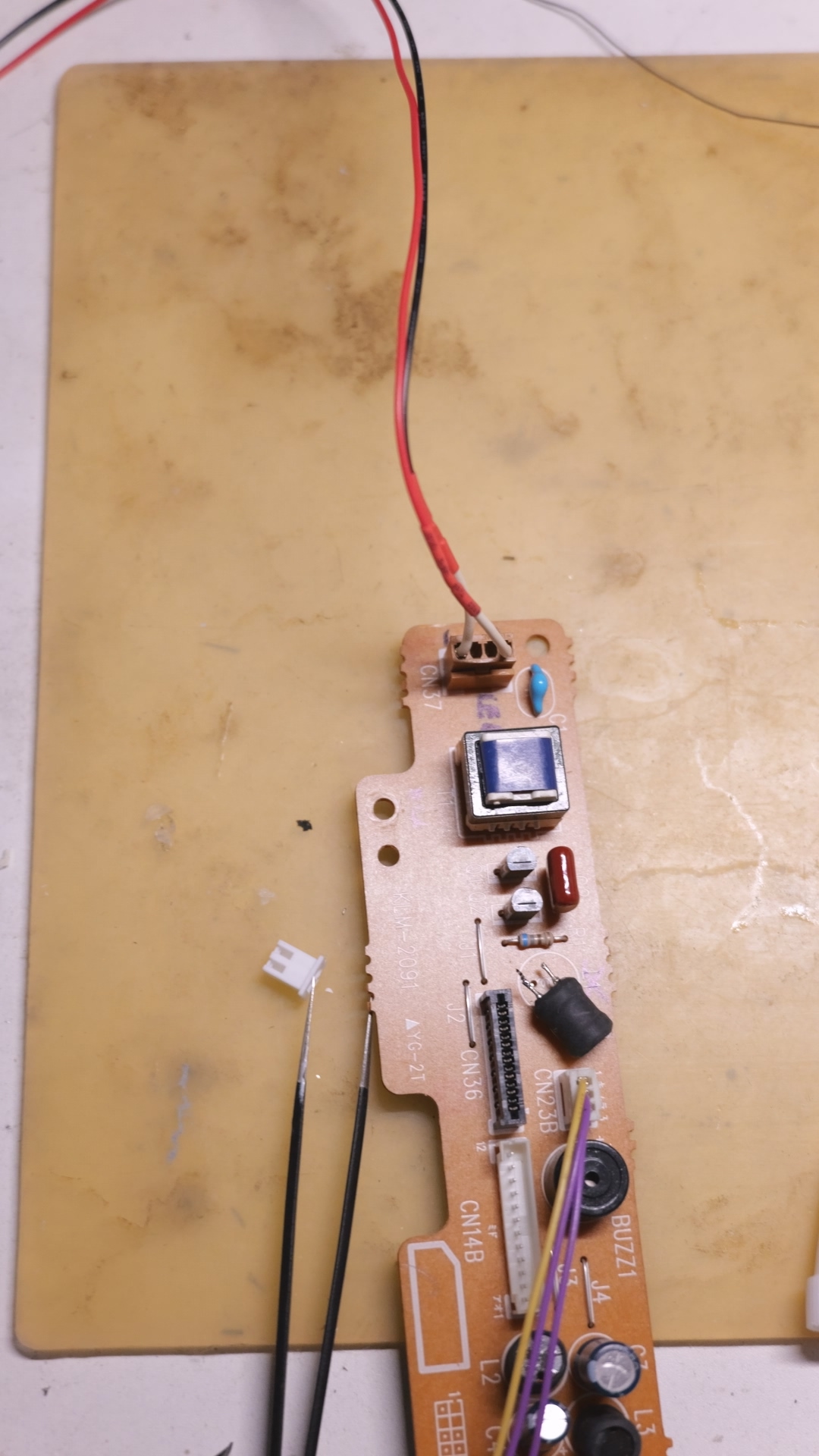

It’s also necessary to modify the backlight circuit. I removed the inductor through which the step-up circuit is powered, and put 5V on the backlight connector.

Replacing FDD with USB FDD

Similar to what I have done with the XP-80, I replaced the FDD with a USB emulator (GOTEK). It was flashed with flashfloppy firmware as well.

Assembling and testing

I used superglue and baking soda to repair the crack on the side cover. I fixed some of the broken boss on the plastic parts. I did thorough cleaning of the surface. I upgraded the synth firmware to latest version .

Before shipping I also recorded the full demo set. You can listen to it at DemoDB: https://demodb.org/korg/triton/triton_classic (English and Japanese UI are available with menu at top right corner)

Also on my Bilibili: https://www.bilibili.com/video/BV12uyAYzEUg